Soundbar Speaker Manufacturing: From Design to Production, The Ultimate Guide

- participación

- Editor

- AUSMAN AUDIO

- Tiempo de Publicación

- 2024/4/30

Resumen

We delve into soundbar speaker manufacturing(From Design to Production), exploring techniques, innovations, and strategies that define the industry.

In this ultimate guide, as sounbar speaker manufacture since 2010, we'll delve into soundbar speaker manufacturing(From Design to Production), exploring techniques, innovations, and strategies that define the industry.

- 1000+ Clients Choose AUSMAN

- Your Ideal OEM/ODM Manufacturer

Action: "Get Custom Solutions Now"

Contents

1. What is A Soundbar?

2. The Market Size of Sound Bars in 2023

3. About Soundbar Speaker Manufacturing Techniques

4. Soundbar Manufacturing Cost Analysis

5. Soundbar Manufacturing Process

6. Embracing Soundbar Manufacturing Innovations

7. Soundbar Speaker Quality Control

8. Managing the Soundbar Speaker Supply Chain

9. Customizing Soundbar Speaker Options

10. Manufacturing Types of Sound Bars

11. How Long Does It Take For Soundbar Prodcution?

12. Soundbar Speaker Manufacturers

13. Conclusion

14. FAQs

1. What is A Soundbar?

A sound bar is a speaker system designed to enhance the audio experience of a television or home theater system.

It is typically a long, narrow speaker unit that can be placed beneath or mounted on a wall below a TV.

The Soundbar speakers are different from party speaker, PA speaker or other speakers, they have emerged as a quintessential component of modern home entertainment systems.

2. The Market Size of Sound Bars in 2023

It is said that, the Soundbar Market Size(Full Report) was valued $6.3 billion in 2023, and is expected to reach $11.8 billion by 2030 with a GAGR of 8.5%.

This shows that it is an industry with good market prospects and an industry worthy of investment.

3. About Soundbar Speaker Manufacturing Techniques

At the heart of soundbar speaker manufacturing are advanced techniques aimed at delivering superior audio performance.

From acoustic engineering design, raw material selection to production technology, there are more than 100 processes in total.

Every detail affects the sound quality and cost of soundbars.

Techniques such as waveguide design, driver placement optimization, and crossover tuning play pivotal roles in shaping the sonic characteristics of soundbars.

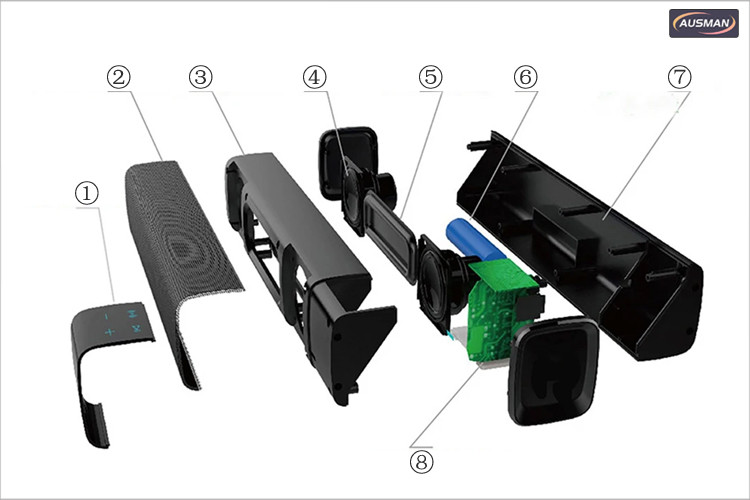

Soundbar Speaker Structure Diagram

4. Soundbar Manufacturing Cost Analysis

The manufacturing cost of a soundbar includes many aspects, such as raw materials (speakers, casings, electronic components), labor, equipment costs, and R&D costs.

Material Costs

Generally speaking, material costs account for 55%-70% of the total manufacturing cost

Labor Costs

Labor costs vary greatly, and labor costs vary from country to country.

It usually accounts for 20%-30% of the total manufacturing cost.

For example, the United States will reach 30%, while China will reach 20%, or even lower.

Manufacturing Cost

Manufacturing overhead costs refer to the indirect costs related to the production of soundbars, including factory rent, utility bills and depreciation expenses, accounting for approximately 5%-10%.

R&D

R&D expenses typically account for 5%-10% of total manufacturing costs.

Take AUSMAN Soundbar AS-HSB101 as an example:

It costs $10 from the factory.

Materials cost $6, labor cost $2.50, manufacturing overhead $1, and research and development expenses $0.50.

Soundbar Speaker Structure Diagram

5. Soundbar Manufacturing Process

The soundbar speaker manufacturing process is not much different from that of other speaker manufacturing, except that the raw materials are much smaller.

This may include design engineering, component sourcing, assembly processes, quality control testing, and packaging.

Setp1

Solution design: including product appearance, sound solution and cost accounting.

Setp2

Raw material procurement: including speaker units, circuit boards, connecting wires, etc.

Setp3

Case production:

There are plastics, alloys, wood, etc. Currently, the Extrusion Molding Process is used the most for mass-produced plastics.

AUSMAN also uses the Extrusion Molding Process to produce soundbar shells.

Setp4

Component processing: such as speaker unit assembly, circuit board welding, etc.

Setp5

Assembly: Assemble the processed components, including the speaker unit, power amplifier board, and crossover into the casing, and then connect the circuits.

AUSMAN has 6 soundbar assembly lines, each production line can produce 3,000 soundbars per day, a total of 18000 pieces.

Setp6

Test: Test items include speaker output power, frequency response, distortion, signal-to-noise ratio, etc.

Setp7

Packaging: Packaging materials need to meet customer and environmental requirements and be able to protect the product from damage.

Action: "Get Custom Solutions Now"

6. Soundbar Manufacturing Innovations

Innovation is the cornerstone of soundbar speaker manufacturing, driving continuous improvement and pushing the boundaries of audio excellence.

From groundbreaking materials like carbon fiber and graphene to revolutionary sound processing algorithms, manufacturers strive to provide users with a better music experience without trying to innovate and breakthrough.

Innovations such as Dolby Atmos integration, wireless connectivity, and voice control capabilities are redefining the way we interact with soundbars, creating immersive audio experiences like never before.

Excellent manufacturers: Samsung, BOSE, SONY

7. Soundbar Speaker Quality Control

Quality control is paramount in soundbar speaker manufacturing, with rigorous testing protocols implemented at every stage of production.

Quality control standards encompass factors such as distortion levels, frequency response accuracy, and durabilitycomply with customer requirements and relevant certification standards such as CE/UL/FCC..

8. Managing the Soundbar Speaker Supply Chain

Effective supply chain management is critical for maintaining a seamless flow of materials and components throughout the manufacturing process.

Collaboration and transparency are key principles in soundbar speaker supply chain management, enabling manufacturers to respond quickly to changing market dynamics and consumer preferences.

9. Customizing Soundbar Speaker Options

Consumer preferences vary widely when it comes to soundbar speakers, with different users seeking unique features and functionalities.

Manufacturers offer a range of customization options, allowing consumers to personalize their soundbars to suit their specific needs.

For example, AUSMAN offers wholesalers more than 100 customization options to meet different regions, brands, performances and cost needs, such as color options, mounting configurations, etc.

10. Manufacturing Types of Sound Bars

The factory produces three models of Sound bars.

Manufacturer's Own Brand Production

For wholesale, distribution or retail

Examples: SONY, BOSE, Samsung, Philips

OEM Production

Some brands or importers do not have their own factories and work with OEMs with production qualifications.

They neither need to invest a lot of R&D funds nor bear production risks.

ODM Brand Development

Some mature brands will develop new sub-brands in order to increase their market share.

Noet: Sometimes, there is no clear distinction between OEM and ODM, and the details of the contract between the two parties need to prevail.

11. How Long Does It Take For Soundbar Prodcution?

There is no fixed standard for the soundbar production cycle.

There are many factors that affect the production cycle: such as factory capacity, order arrangements, order volume, raw material supply, equipment factors (new/old), production failures, worker factors, holidays, natural disasters, etc.

The following is a reference for the production cycle of AUSMAN soundbar:

Purchasing raw materials: 10-15 days

Production parts: 15-20 days

Sound Blaster Assembly: 5-10 days

Testing and Quality Control: 5 days

Customer inspection: 7 days

These are only reference values and the actual production cycle will vary.

AUSAMA Soundbar Production Timeline and Shipment

|

Order Quatity

|

Production Time

|

Shipment Term

|

|

1000 Units ≦

|

15 Days

|

15-20 Days

|

|

1000-5000 Units

|

20 Days

|

20-30 Days

|

|

5000-10000 Units

|

30 Days

|

30-40 Days

|

10000-50000 Units | 45 Days | 45-60 Days |

12. Soundbar Speaker Manufacturers

World Famous Sound Bar Brands

The total number of global Soundbar manufacturers or brands is estimated to be more than 10,000.

Here we list some leading manufacturers.

Samsung

LG

Harman Kardon

Soundbar OEM Manufacturers From China

The total number of global Soundbar manufacturers or brands is estimated to be more than 10,000.

Here we list some leading manufacturers.

IBR

ACOUSTIC

Creative

Microlab

13. Conclusion

The sales and quality of Soundbars are constantly improving.

We believe that manufacturers will continue to update the soundbar speaker manufacturing process to offer more high-quality, intelligent Soundbar speakers.

FAQs

1. What are the key components of a soundbar speaker?

A soundbar speaker typically consists of speaker drivers, amplifiers, signal processing circuitry, and enclosure materials.

Each component plays a crucial role in delivering high-quality audio performance.

2. What are the advantages of soundbar speakers over traditional speaker systems?

Soundbar speakers offer several advantages, including space-saving design, simplified setup, and immersive sound quality.

They are also ideal for home environments where space is limited or for users seeking a clutter-free audio solution.

3. What materials are commonly used in soundbar speaker construction?

Soundbar speaker enclosures are often made from materials such as plastic, wood, or metal alloys, chosen for their acoustic properties and durability.

Speaker drivers may be constructed using materials like paper, polypropylene, or composite materials, depending on the desired audio characteristics.

4. Can soundbar speakers be customized to fit specific requirements?

Yes.

Many manufacturers offer customization options for soundbar speakers, allowing consumers to choose features such as color, size, connectivity options, and audio presets.

Customization options cater to individual preferences and enhance the overall user experience.

5. What are some emerging trends in soundbar speaker manufacturing?

Emerging trends in soundbar speaker manufacturing include the integration of smart technologies such as voice assistants, wireless connectivity, and advanced audio processing algorithms.

6. Are soundbar speakers compatible with various audio sources and devices?

Yes.

Soundbar speakers are designed to be compatible with a wide range of audio sources and devices, including TVs, Blu-ray players, gaming consoles, smartphones, and streaming devices.

They typically feature multiple connectivity options such as HDMI, optical, Bluetooth, and Wi-Fi for seamless integration with different devices.

Need Soundbar Speaker OEM Solutions?

If you are a wholesaler, importer, or audio supermarket of Soundbar and are looking for low-priced Soundbar OEM cooperation, please contact us.

We are a professional manufacturer and exporter who will provide you with competitive OEM solutions.

- Our Expertise Lies in Customizing Speakers to Perfectly Align with Your Market.

- We Can Help You Realize It